Fibreglass Pump Stations

- Duplex Pressure Sewer

- Triplex Pressure Sewer Drawings

- Air Valve Kits

- Boundary Connection Kits

- Flushing Point Kits

- Isolation Valve Kits

- Concrete Pump Stations

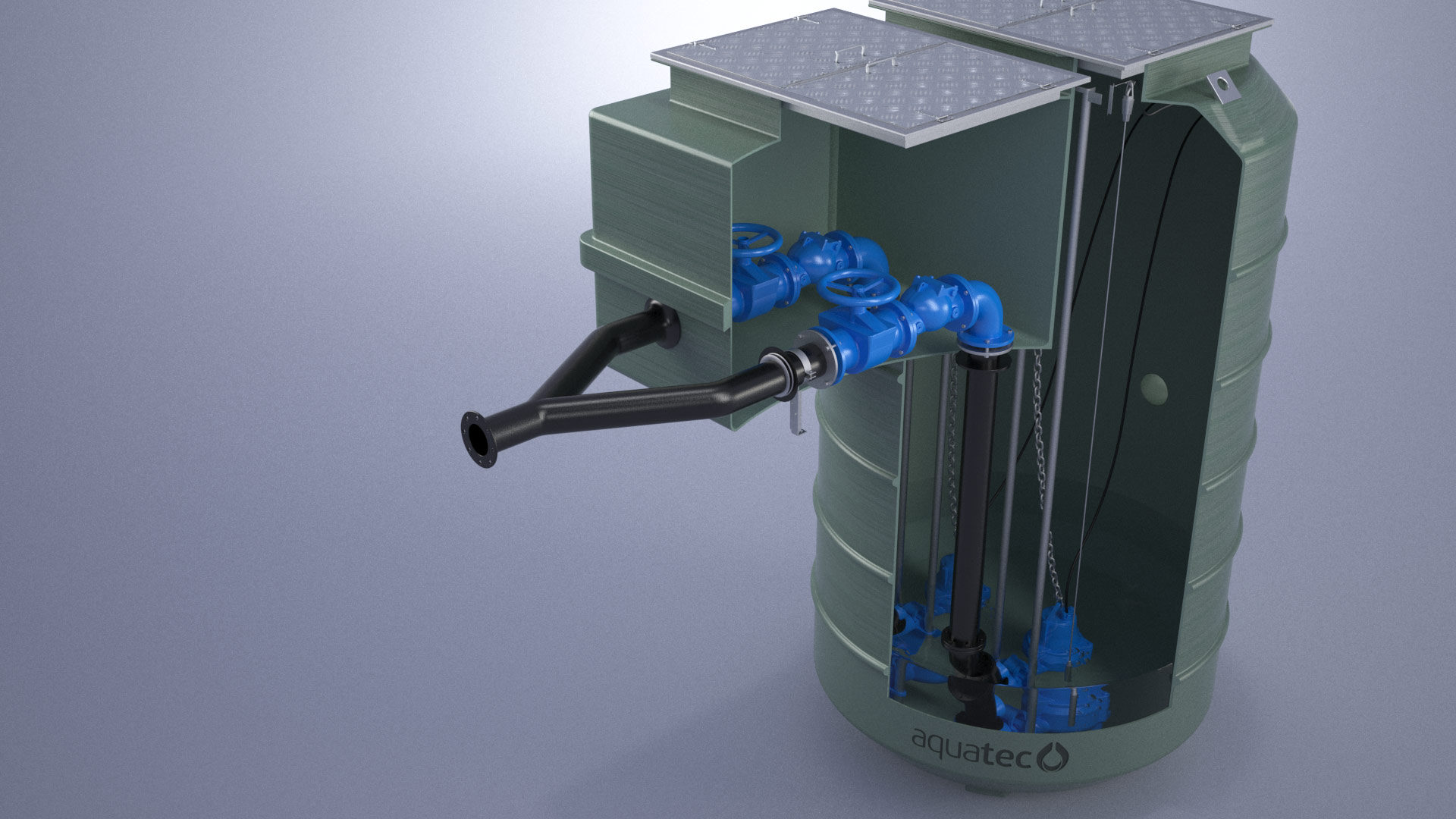

- Fibreglass Pump Stations

- Storage Vessels

- Simplex Pressure Sewer Drawings

- Enduraplex Pressure Sewer

- Enviroplex Pressure Sewer

Aquatec’s fibreglass pump stations are manufactured as a one-piece vessel to exact project specifications, allowing for a seamless installation process.

Download our PDF and CAD drawings to learn more.

Related Documents

Download File

Please register to gain access to download files.

Thank you for registering.

Your file will automatically download.