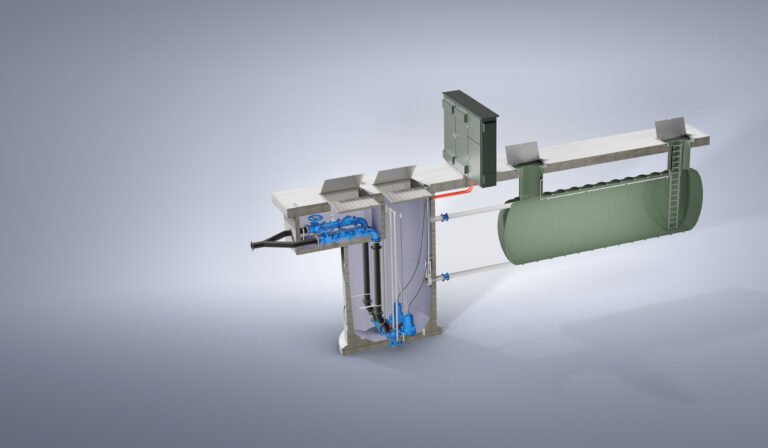

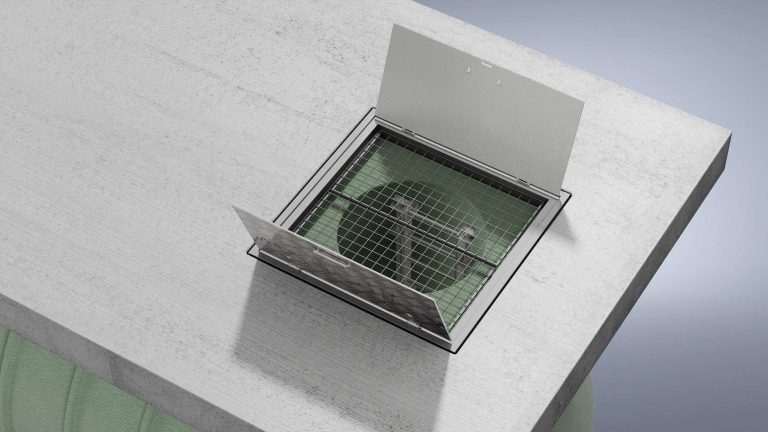

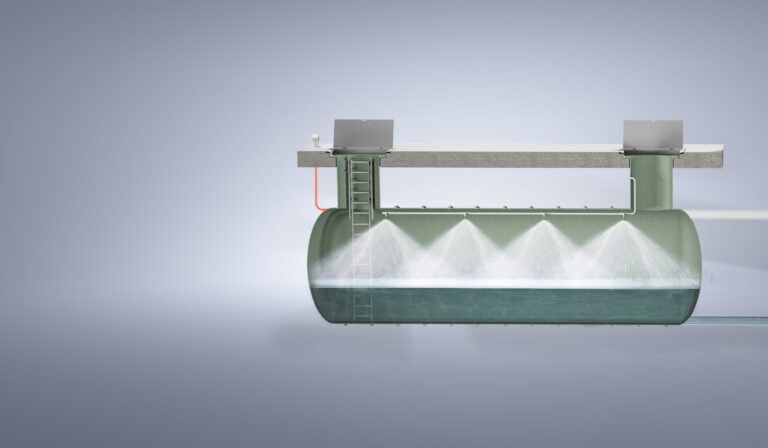

Each vessel is manufactured as a completely sealed, one-piece unit. All penetrations and wall fixings in the structure are carried out in the factory with compatible materials to eliminate the possibility of ingress or egress.

Aquatec’s fibreglass storage vessels are structurally engineered to deliver on individual project specifications. Our technical consultants respond to pre-planned specifications, or submit recommendations to meet operational requirements and site conditions.